A new dimension in gas bubble detection in water basins

MACEAS’ ultrasonic leak testing provides accurate leak detection and localisation at minimal operating costs, making it ideal for automated processes. Take advantage of this low-maintenance solution to increase the efficiency and quality of your manufacturing process and quality assurance.

Leak testing is a crucial step for quality assurance in industrial production. With its ultrasonic leak testing, MACEAS offers a modern, high-precision solution that both detects leaks and pinpoints their exact location. By using compressed air as the test gas and robust, maintenance-free ultrasonic sensor technology, our customers benefit from minimal operating and maintenance costs. This method is ideal for fully automated production processes and ensures transparent, reliable testing – without the need for periodic calibrations or time-consuming preparation of the test parts. You can trust MACEAS to make your production processes more efficient and your products more durable!

Your benefits at a glance:

- Objective, transparent leak testing

- Several parts can be tested in one basin

- Direct, localising measurement method

- Low test gas costs thanks to use of air or nitrogen as test gas

- Semi-automatic or fully automatic leak testing systems

- Low-maintenance ultrasonic system

- No periodic calibration required

- No vacuum components necessary

- Low operating costs

- Product holder for other product variants

How ultrasonic leak testing works

Detect and locate leaks down to 1 · 10–4 mbar · l/s using ultrasonic leak testing

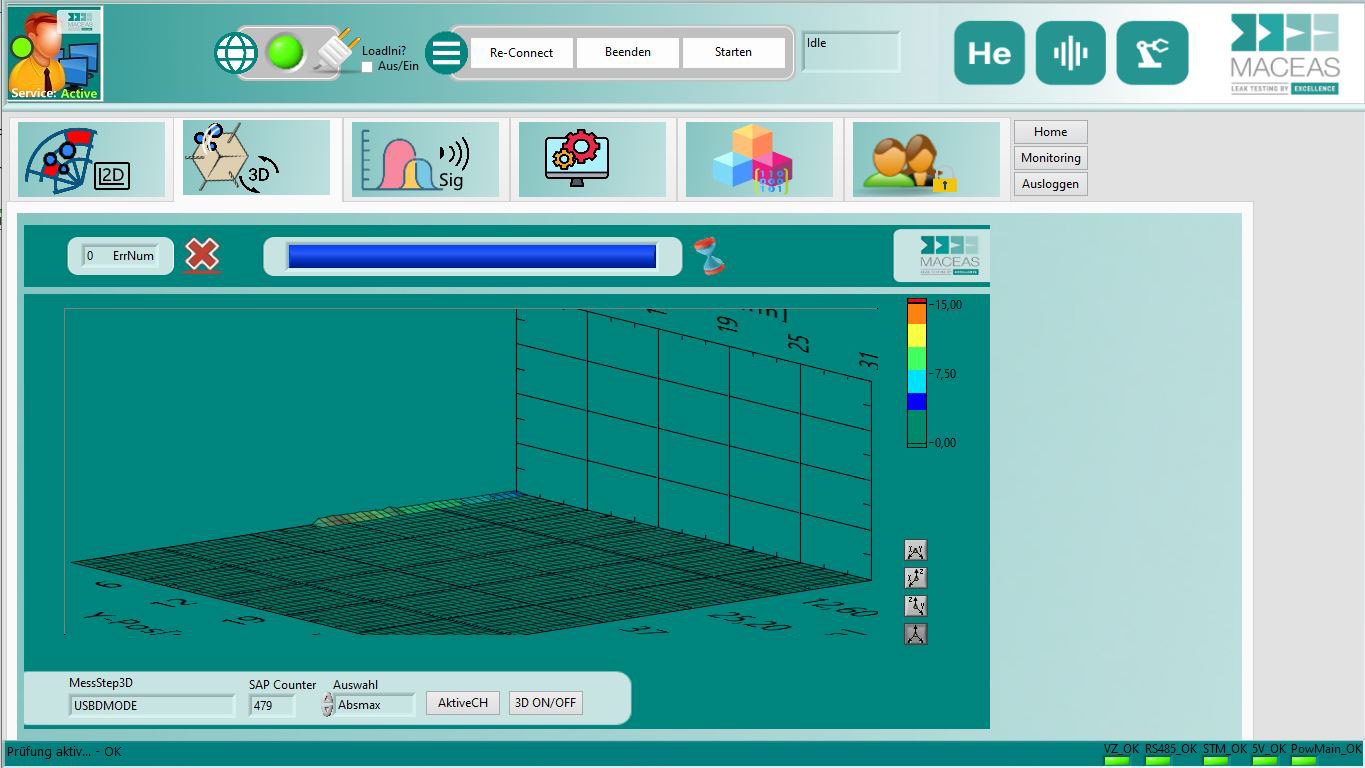

Visualisation of ultrasonic gas bubble detection in a water basin

Ultrasonic leak testing

Ultrasonic leak testing enables precise, reliable detection of gas bubbles in a water basin. This operator-independent, automated process minimises human error and increases efficiency even with low leak rates.

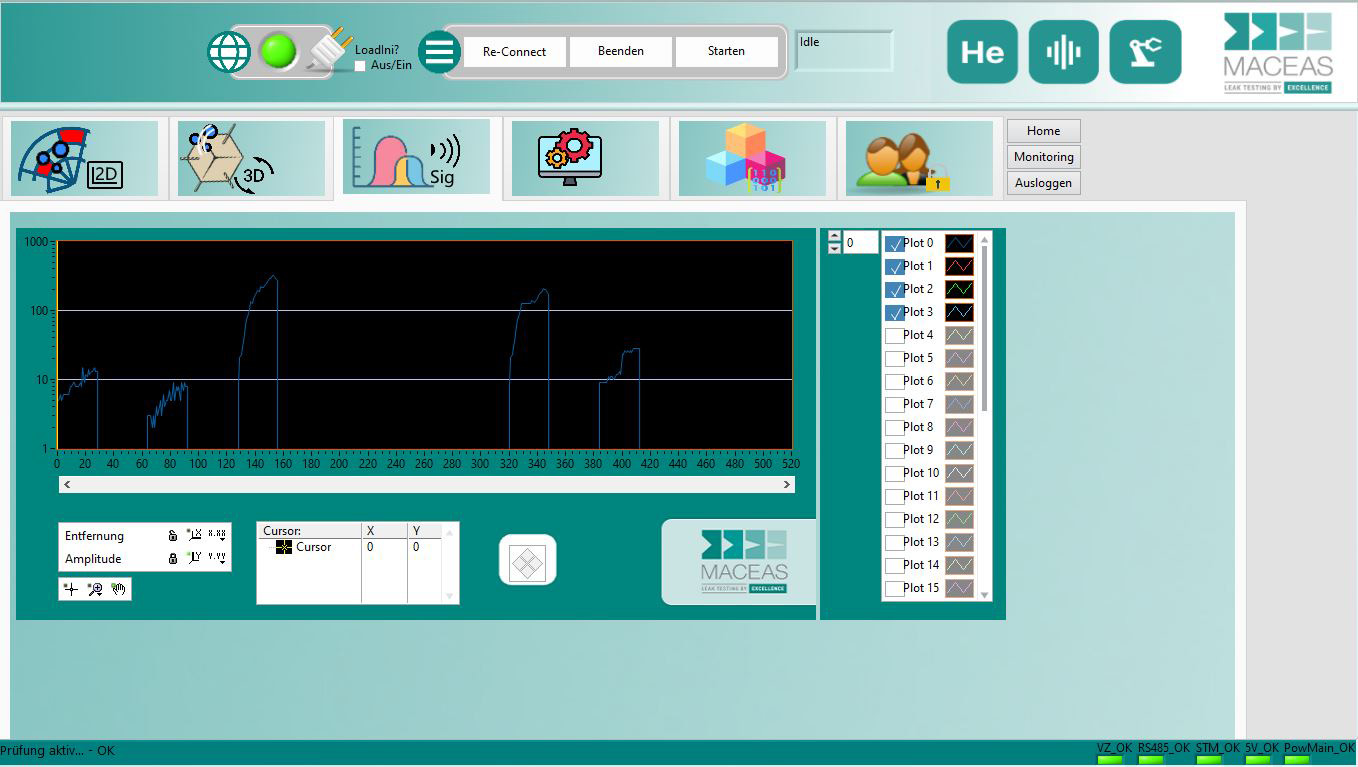

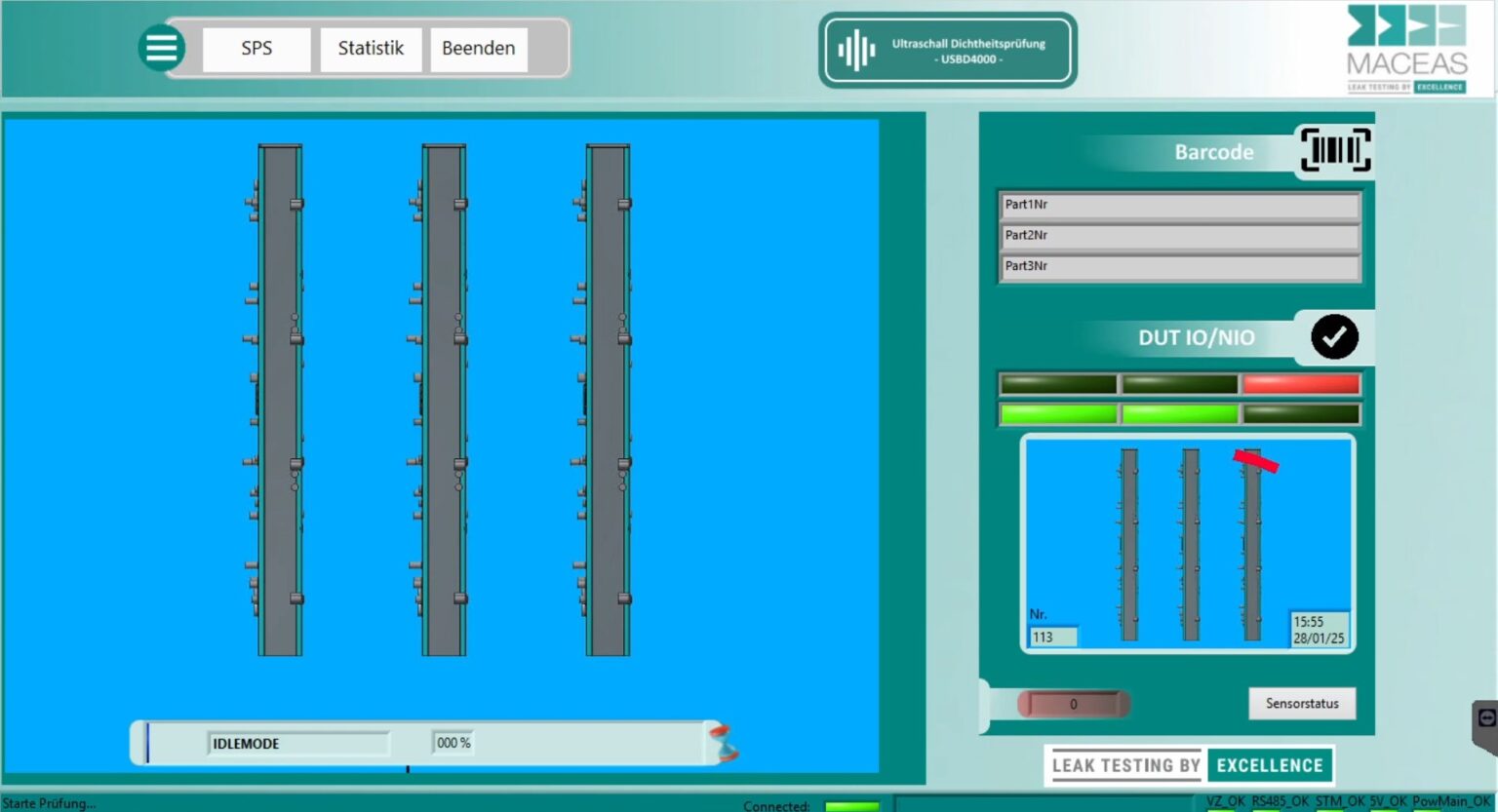

Visualization of ultrasonic leak testing with the USBD4000

This visualization shows the USBD4000 in use. The test specimen is completely immersed in the water bath so that even the smallest leaks can be detected. Gas bubbles escape from the leak and rise in the water. When these bubbles pass through the sound field of the USBD4000, they are detected by the ultrasonic system. In this way, the leak can be reliably detected and precisely located.

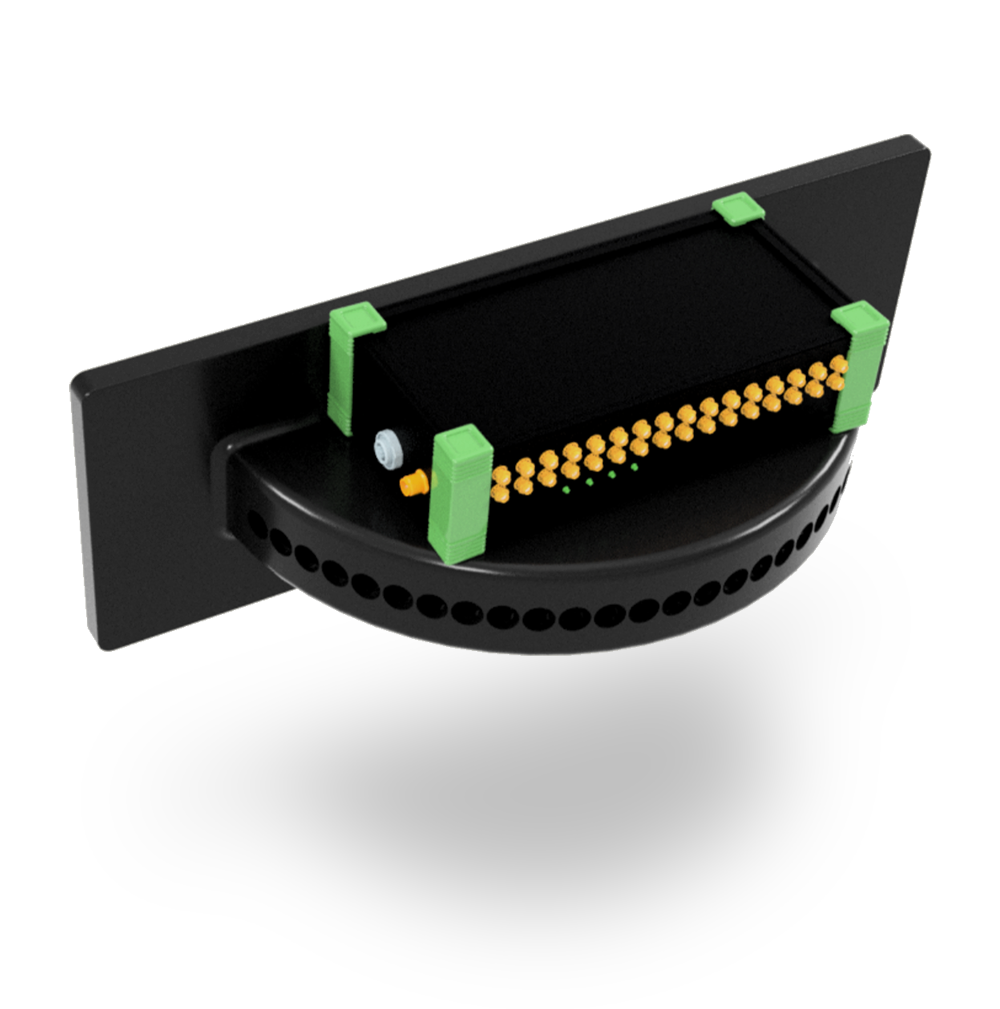

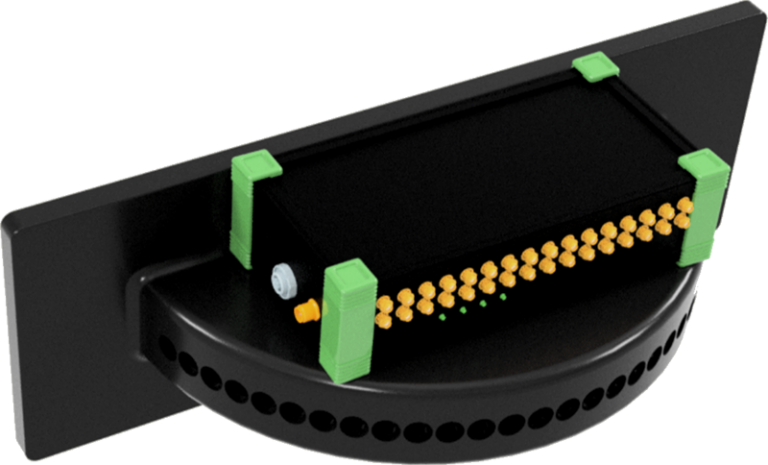

New USBD4000

MACEAS sensor unit for ultrasonic leak testing:

Latest testing technology with 3D leak detection and related software

USBD4000

What does that mean? 25 years of experience in ultrasonic leak testing in compact, next-generation hardware and software:

- Next-generation hardware that is easy to install and compatible with all MACEAS systems

- Preventive maintenance with real-time, long-term data

- Improved signal processing and interference suppression

- Precise leak detection and real-time measurement results

- Efficient error handling and user management

Complete package comprising measuring technology and software

from € 57,300.00

Flexible system – precise results

The USBD4000 offers a reliable solution for a broad range of requirements. The basic structure and scope of delivery remain the same, but the number of ultrasonic sensors varies. This determines the size of the sound and test field and consequently the maximum size and the number of workpieces to be tested. This enables us to tailor the inspection perfectly to your individual needs – for maximum precision and efficiency.

| USBD3000 Previous Generation | USBD4000 New Generation |

|

|---|---|---|

| Real-time display of measurement results | ||

| Diagnosis and remote maintenance without interrupting production | ||

| Next-generation, high-performance hardware platform | expired | |

| Next-generation, high-performance hardware platform | ||

| Less sensitive to faults thanks to compact design | Up to 10 m measuring cable | approx. 25–30 cm |

| Spatial leak detection | ||

| Combinatorial parameterisation to reduce the amount of data |

| Variante | Preis |

|---|---|

| 16 sensors | 57,300.00 € |

| 20 sensors | 60,000.00 € |

| 24 sensors | 62,750.00 € |

| 29 sensors | 66,500.00 € |

Key advantages of MACEAS ultrasonic leak testing

Automation instead of manual inspection

Our ultrasonic leak testing automates the entire process and monitors every point of the test piece throughout the entire measuring time. This eliminates time-consuming manual checks and ensures that potential leaks are not overlooked.

Precise leak detection

Compared to the helium sniffer solution, where each position is only briefly scanned and slight air turbulence can delay the detection of leaks, our ultrasonic measurement permanently checks every relevant measuring point with a guaranteed leak rate. This allows even the smallest leaks to be reliably located, significantly improving quality assurance.

Savings through efficiency

Continuous monitoring of all measuring points significantly reduces testing times. At the same time, maintenance and operating costs are reduced compared to more complex helium sniffer solutions. This optimises resource utilisation and increases the cost-effectiveness of series production.

Technical data

Active sensor unit

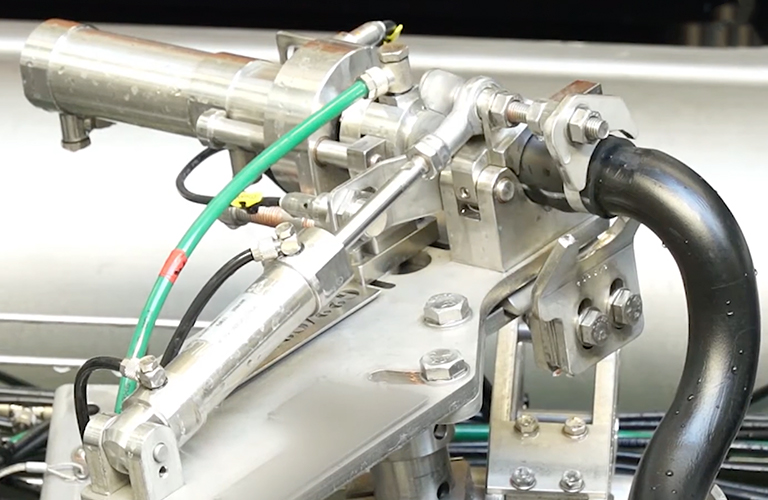

The active sensor unit consists of a sensor holder with up to 29 ultrasonic sensors, screened-off sensor cables, active sensor electronics (with measuring electronics) and a protective hood.

Control computer with Windows 10 or Windows 11 IOT

The control PC is used for higher-level measurement sequence control and enables the customer to operate the system intuitively. We also carry out the entire parameterisation via the control PC. Remotely as well, if required.

Active sensor electronics

| Power supply: | 24 VDC |

| Power consumption: | 10 W |

| Interface: | 100 Mbit/s Ethernet |

| Sensor connections: | 32 SMA-Buchsen |

| Signalling: | 3 status LEDs |

Intuitive control and monitoring via display

The system is equipped with a user-friendly display for easy operation and monitoring of the test process. The display can be used to set important parameters and view real-time leak detection data, enabling efficient, precise control.

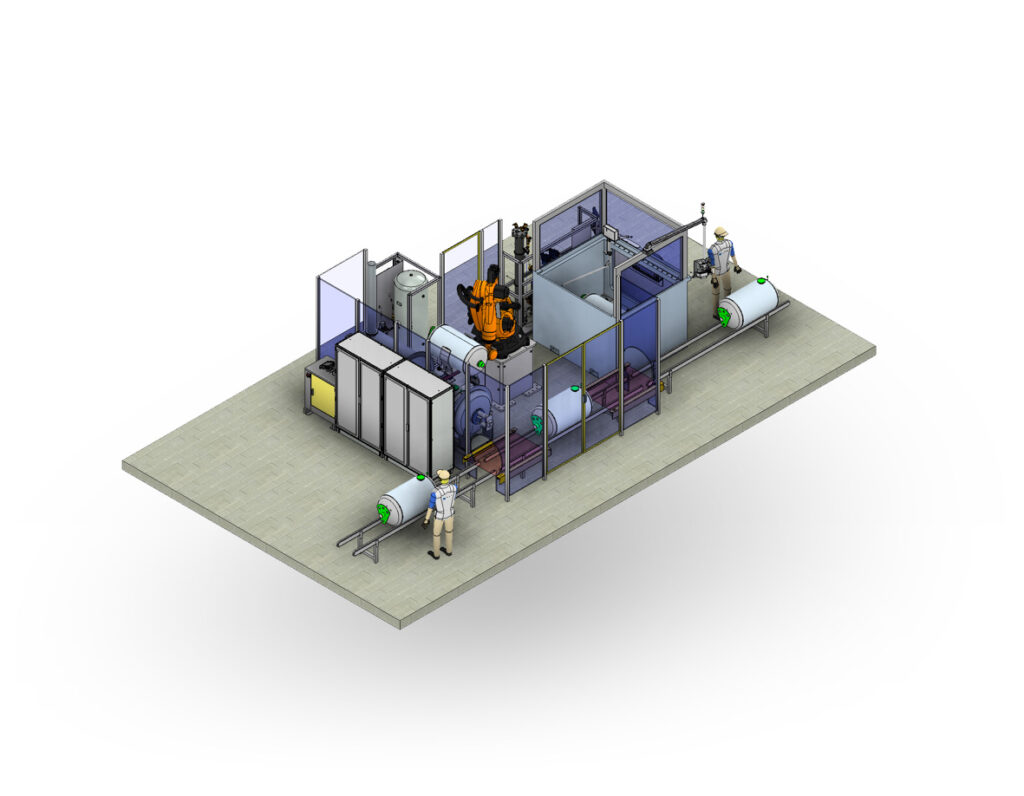

Integration in a production line for quality control

The sensor unit for ultrasonic leak testing can be easily integrated into existing production lines and enables automated inline quality assurance. The precise detection and localisation of leaks during the production process ensures seamless control without interrupting the workflow.

Applications

MACEAS ultrasonic leak testing offers a wide range of applications in various industries – from the automotive industry to the energy sector. Regardless of whether it is filler pipes, fuel tanks, hot water tanks or battery packs – this innovative test method ensures the highest quality and safety through precise leak detection and localisation for a wide range of products and industries.