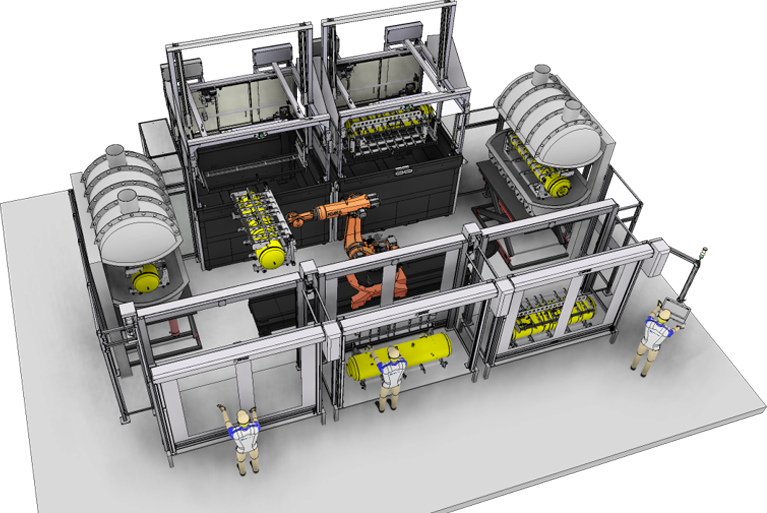

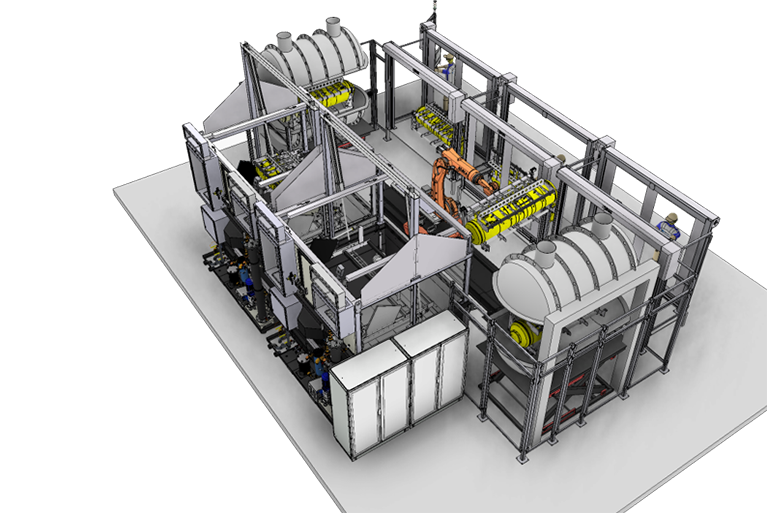

Innovative: Detect and localize leaks reliably with the help of ultrasound, but also carry out a pressure holding test

Not only the automotive industry has special quality requirements for its products, but other industries also manufacture products that place high demands on a corresponding tightness. Among other things, the leak test of hot cylinders (boilers) from the heating, building, water management and energy sectors should be mentioned here.

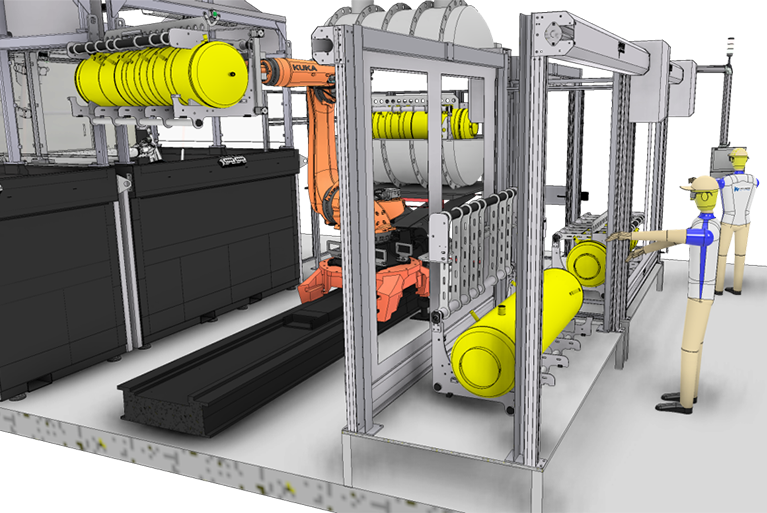

The ultrasonic leak test offers several advantages. On the one hand, a leak rate of up to 1 ⋅ 10−4 mbar ⋅ l / s can be detected and, on the other hand, the leak can also be localized. Furthermore, a large number of variants can be covered with just one leak test system. A special innovation is the integrated interaction and combination of leak testing and an integrated pressure holding test.

From practice

Ultrasonic leak test – hot water cylinders (boilers)

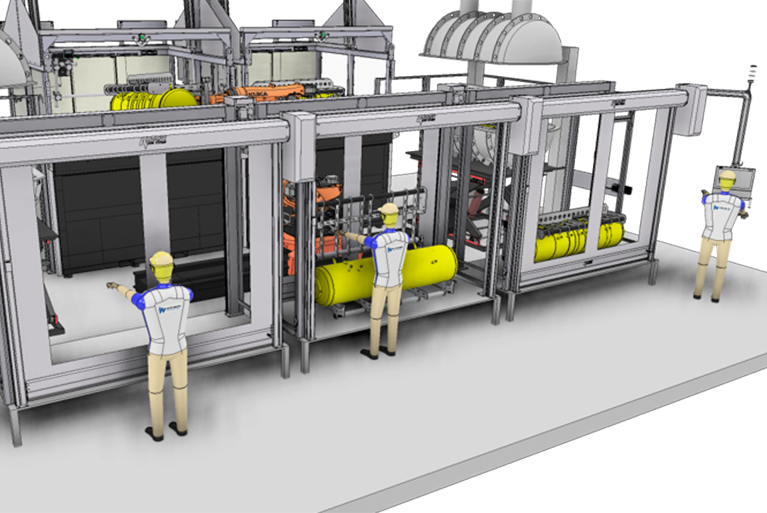

Technical specifications

- Leak rate: 1 ⋅ 10−2 mbar ⋅ l / s

- Pressure: 1,45 bar (low pressure) und 5,0 bar (high pressure)

- Cycle time: 120 – 220 Sekunden, abhängig vom Behältervolumen

- Test gas: 100% air