Green hydrogen as a key element of the energy transition offers a multitude of possibilities and opportunities in the automotive and transport sector as well as in energy storage and sector coupling.

Leak testing in hydrogen technology

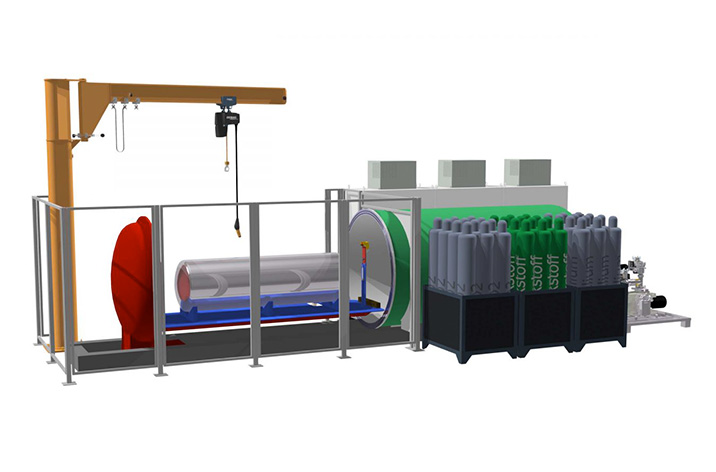

Hydrogen is an important part of the energy transition. Electrolysers and fuel cells as well as the storage of green hydrogen will play a decisive role in achieving the climate goals. We already offer innovative and reliable equipment for leak testing of bipolar plates for fuel cells. The leak testing of hydrogen pressure vessels and cryogenic hydrogen tanks is only one part of our product portfolio in hydrogen solutions.

From practice

Helium leak test – Bipolar plate

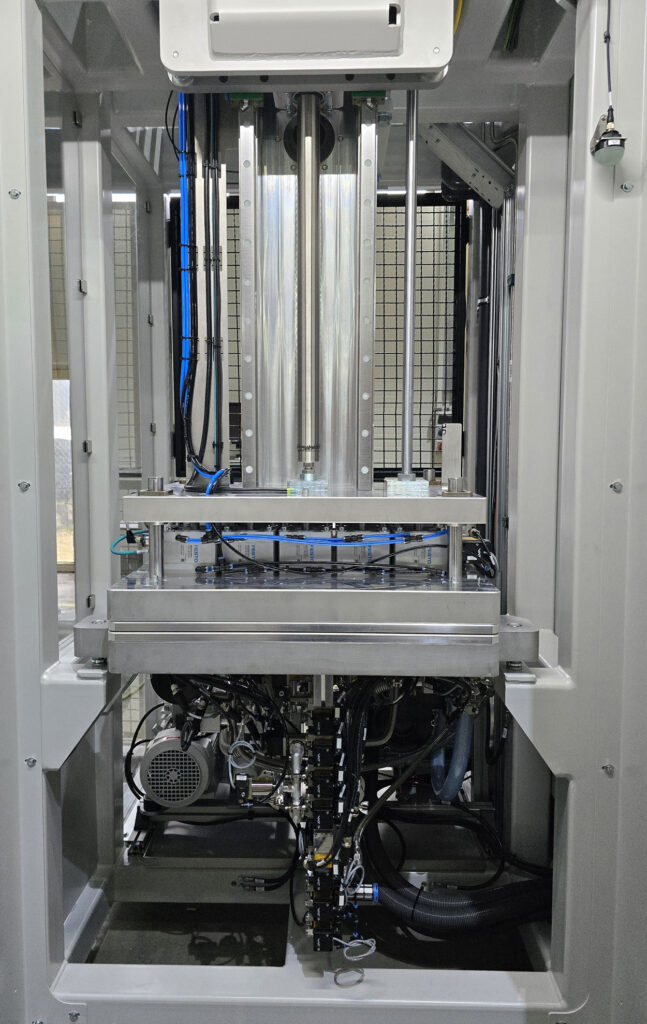

Technical specifications

- Effective cycle time: 12 s

- Capacity: 300 parts / h

- Test gas: 10% helium / 90% air

- Leak rate: 4.8 ⋅ 10−5 mbar ⋅ l/s

Semi-automatic leak test of metallic or graphite bipolar plates with and without seals on the bipolar plate.

Leak testing of bipolar plates –

your reliable testing service for samples, prototypes and small series

The leak tightness of bipolar plates is crucial for the performance, durability and safety of fuel cells and electrolyzers. To ensure this, we offer you a specialized testing service that saves you having to set up your own testing facilities during the development process.

Why our testing service?

When developing new products or manufacturing small batches, setting up your own leak testing system is often uneconomical and time-consuming. Our service allows you to concentrate fully on your core competencies while we reliably take over the leak testing of your bipolar plates.

What we offer:

- Testing of samples and prototypes: We test your first prototypes for leak tightness and help you to identify and rectify design or manufacturing weaknesses at an early stage.

- Leak testing for small series: Even when producing smaller quantities, we ensure that every bipolar plate meets the high requirements for tightness and reliability.

- State-of-the-art testing methods: We use the latest testing methods to simulate real operating conditions in order to detect and rule out even the smallest leaks.

Your benefits:

- Cost efficiency: Save yourself the investment in expensive testing equipment for the time being and use our service to respond flexibly and cost-effectively to your testing requirements.

- Fast results: We provide you with fast and accurate test results so you can continue your development and production processes without delays.

- Expert knowledge: Benefit from our many years of experience and specialized know-how in the field of bipolar plate leak testing.

Rely on our expertise and take the next step towards safe and efficient production. Contact us for a customized test offer or more information about our service.

Areas of application

Whitepaper: A Hydrogen Future? Far from Simple.

What is necessary for a reliable assessment of the economic production of metallic bipolar plates for fuel cells and electrolyzers? And how can corresponding manufacturing processes be scaled and standardized? Answers to these and many other questions can be found in the whitepaper “In Future Hydrogen? Anything but simple.” by Graebener®.

MACEAS played an important role in the creation of the white paper and makes both the white paper and the process navigator available to download.

To receive the whitepaper, please enter your e-mail address in the field below. After clicking on the registration link in the confirmation e-mail, you will receive access to the whitepaper and agree that we will continue to inform you about our products and services by e-mail in the future.

Request whitepaper

Explainer video: Bipolar plate leak test

Discover now

MACEAS systems on Hyfindr

Hyfindr is a new B2B marketplace for technical components, systems and services for the hydrogen and fuel cell industry. MACEAS is represented with various systems on the platform.