MACEAS – Your Expert for Leak Testing Services and Quality Assurance!

Ensure the highest quality and safety for your products! Our testing service verifies your products for leaks and defects before they enter the market. Thanks to our modern measurement technology and specialized leak tests, we guarantee precision and detect even the smallest leaks. Put your trust in our expertise – from prototypes to small series – for reliable products without undesired failures.

Do you want to ensure that your products meet the highest quality standards? Our contract leak testing service ensures that your products are thoroughly checked for defects and leaks before they reach the market.

Precision is key! With our contract leak testing solutions, we ensure that your products meet the exact specifications. Our state-of-the-art measurement technology ensures maximum precision.

Leaks can have costly consequences. With our leak testing, we ensure that your components and assemblies are leak-proof and meet the highest standards of quality and safety. Our leak tests are designed to detect even the smallest leaks.

Trust us to increase the reliability of your products and avoid undesired failures.

Whether it’s sample parts, small series or prototypes – our leak testing guarantees you the highest quality and safety at every stage of production.

Why choose MACEAS

our top priority

Our leak testing methods

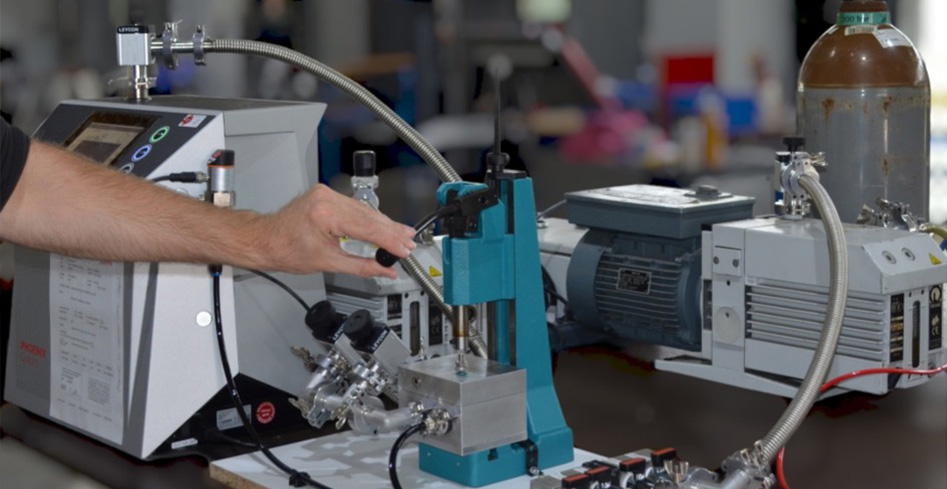

Our core competence, leak testing with a trace gas such as helium, is a reliable method for detecting leaks in industrial applications. Thanks to the small molecular size of the trace gas, even the smallest leaks can be precisely identified.

Helium vacuum leak testing

In the helium-vacuum method, a test object is placed in a vacuum test chamber. Then, the chamber and the test object are evacuated. Once the target vacuum has been reached, helium is introduced into the test object at test pressure while a mass spectrometer detects the helium concentration in the chamber. An increase in this concentration indicates a leak in the test object. This method is used in industries with high leak tightness requirements due to its high sensitivity and accuracy.

Helium sniffing method

In the helium sniffing method, the test object is pressurized above atmospheric pressure. This is done with helium, a helium mixture or forming gas. The escaping tracer gas at potential leaks is then detected from the outside using a “sniffer” probe connected to a mass spectrometer by passing it over the surface of the object. An increase in the helium concentration at the detector indicates a leak. This method is particularly suitable for pinpointing leaks.

Ultrasonic leak testing

In the ultrasonic gas bubble detection method, the object to be tested is immersed in a water bath and pressurized. If it is leaking, gas bubbles escape from the object. This technique is reminiscent of the classic patching of bicycle inner tubes, where leaks are made visible by air bubbles rising in the water. In an industrial context, ultrasound is used to detect and precisely localize the escaping gas bubbles.

From practice

The new ferry ship in Europe, the “FS RICHMOND” of Stadtwerke Konstanz GmbH on Lake Constance, is the first inland passenger and ferry vessel in Europe with high-speed pure gas engines, which can be operated with bio-LNG in a greenhouse gas-neutral manner.

As part of the commissioning of the new LNG ferry ship “FS RICHMOND”, the MACEAS service team was commissioned by Stadtwerke Konstanz GmbH to check the insulation tank of the ferry’s vacuum-insulated double-walled LNG tanks for leaks.

Source: www.stadtwerke-konstanz.de | Photo: www.now-gmbh.de

Ferry ship "FS RICHMOND“

- Width: 13,4 m

- Weight: ca. 840 t

- Passengers: 700

- Vehicles: 64 cars

- Power: 2 × 746 kW

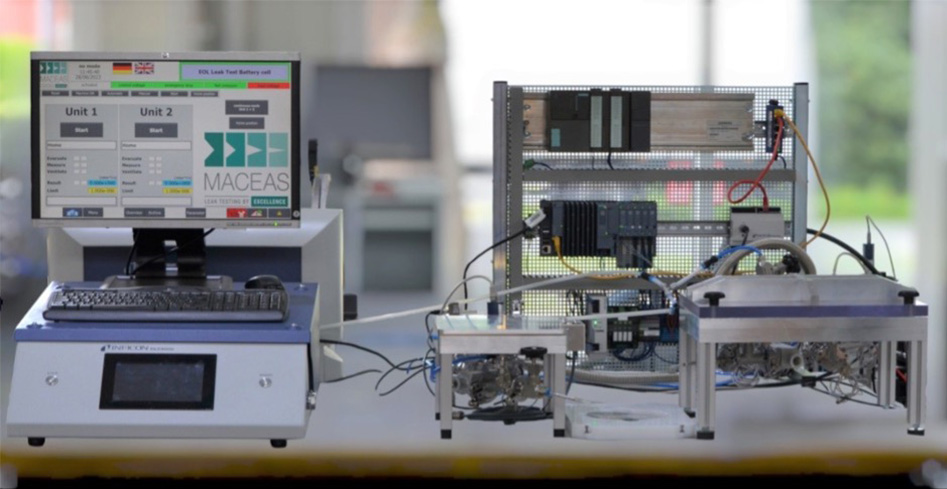

MACEAS also offers its customers the possibility to test parts, components, samples, pre-series, etc. for tightness. Two test stations with corresponding test chambers are available for this purpose. Please do not hesitate to contact us!

Contact

Contact us today to find out more about our services and how we can help you with the quality assurance of your products.

We look forward to working with you.